THUNDER BAY, ON / ACCESSWIRE / October 3, 2024 / Clean Air Metals Inc. ("Clean Air Metals" or the "Company") (TSXV:AIR)(FRA:CKU)(OTCQB:CLRMF) is pleased to announce additional high-grade drilling results from the Current deposit at its 100%-owned Thunder Bay North Critical Minerals Project ("TBN").

Assay highlights include:

50.7 m of 4.52 g/t Pt, 4.38 g/t Pd, 0.99% Cu and 0.53% Ni(13.74 g/t Pt.eq1; 4.36% Cu.eq2) from 82.0 m downhole in Hole CL24-010, including

6.35 g/t Pt, 6.10 g/t Pd, 1.32% Cu and 0.69% Ni over 30.7 m from 102 m,

38.4 m of 3.38g/t Pt, 3.26g/t Pd, 0.72% Cu and 0.45% Ni (10.32 g/t Pt.eq1; 3.27% Cu.eq2) from 153 mdownhole in Hole CL24-005, including

13.2 m of 8.39g/t Pt, 8.09 g/t Pd, 1.75% Cu, 0.95% Ni from 178.2 m. and;

20.40 g/t Pt, 21.00 g/t Pd, 4.20% Cu and 2.18 % Ni over 0.5 m from 188.9 m. (Massive Sulphides)

23.3 m of 4.54 g/t Pt, 4.23 g/t Pd, 1.11% Cu and 0.60% Ni (14.20 g/t Pt.eq1; 4.51% Cu.eq2) from 154.7mdownhole in Hole CL24-008, including

13.8m of 6.01 g/t Pt, 5,56 g/t Pd, 1.45% Cu, 0.75% Ni, from 159.0 m.

19.3 m of 3.61 g/t Pt, 3.26 g/t Pd, 0.79% Cu and 0.38% Ni (10.75 g/t Pt.eq1; 3.40% Cu.eq2) from 150 mdownhole in Hole CL24-006, including

10.8 m of 5.33 g/t Pt, 4.65 g/t Pd, 1.13% Cu, 0.40% Ni from 157.0 m.

Notes

Platinum equivalent are calculated as follows: Pt.eq = (Pt grade/31.1035 x $982 + Pd grade x 31.1035 x 86.2% x $1,057 + Cu grade x 2204 x 95.9% x $4.27 + Ni grade x 2204 x 57% x 7.58 + Au grade/31.1035 x 85% x $2,642 + Ag grade/31.1035 x 65.2% x $31.73) / $982 x 31.1035

Copper equivalents are calculated as follows: Cu.eq= (Cu grade x 2204 x $4.27 + Pt grade x 31.1035 x 80.6% x $982 +Pd grade x 31.0135 x 86.2% x $1,057 + Ni grade x 2204 x 57% x $7.58 + Au grade/31.1035 x 85% x $2,642 + Ag grade/31.1035 x 65.2% x $31.73) / $4.27 / 2204

Equivalents are based on the following recoveries Pt 80.6%, Pd 86.2%, Cu 95.9% Ni 57%, Au 85%, Ag 65.2%; and metal prices from September 25, 2024 US Spot; Pt $982, Pd $1057, Cu $4.27, Ni $7.58, Au $2642, Ag $31.73

A summary of all assays is presented in Table 1.

Clean Air Metals' CEO Mike Garbutt commented, "The new drilling results confirm our belief that the tonnage of the highest-grade parts of the Current deposit is likely underestimated by the most recent resource model - largely because of an inadequate drilling density in these areas. Additional geophysical modeling and tightly-spaced drilling is expected to allow us to quantify the highest value mineralization within both the Current and Escape deposits. We believe that a more robust, low-tonnage high-grade production model anchored by these high-grade areas is attainable."

The summer drilling program targeted near-surface high-grade zones within the Current deposit to better define their lateral continuity and tonnage potential. These new results, in conjunction with the initial assays (see September 9th release), confirm that high-grade mineralization in the areas targeted extends beyond what was outlined in the most recent resource model (NI 43-101 technical report on the Thunder Bay North Project, Ontario, Canada, SLR Consulting Canada Ltd, June 19, 2023).

Results Confirm Improved High-Grade Continuity

The revised geological model for the high-grade areas at Thunder Bay North employs flow processes similar to those associated with alluvial gold processes. These results provide confidence and "proof of concept" that continued success in the expansion of the high-grade pods along strike is possible with tighter drilling. The Company believes that a predictive tool based principally upon geophysical data can quickly be developed that will allow the identification of additional high-grade pods that occur within the Current and Escape deposits.

Clean Air Metals' Vice President of Exploration, Lionnel Djon commented, "The results of the proof-of-concept drilling at Current provide a high level of confidence that the high-grade pods have a regular periodicity that can be predicted using 3D geophysical models and that their tonnage potential is likely greater than previously appreciated. We are excited to follow up on these encouraging results and begin the job of delineating these high-grade domains to support an independent estimation of their tonnage and grade."

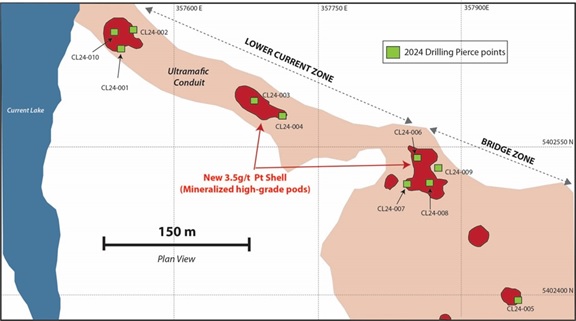

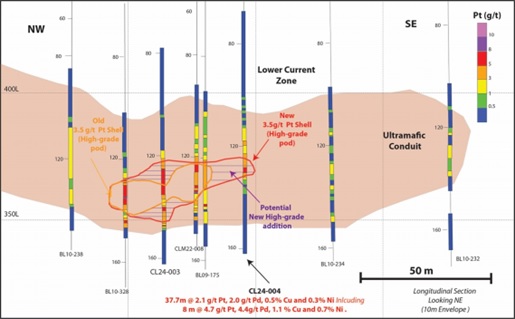

Drilling at four high-grade target areas has produced exceptional results. Nine of the ten holes completed in the program intersected significant widths of high-grade mineralization, defined here as averaging over 6 g/t combined Pt and Pd. Hole locations relative to the high-grade targets and the different mineralized zones within the Current deposit are shown in Figure 1. Figure 2 outlines an area in the Lower Current Zone where the program delivered improved grade, continuity and volume, expanding the high-grade zone to the southeast.

Figure 1. Plan view map showing drill hole locations for the recently completed 10-hole program at the Current deposit.

Figure 2. Section showing CL24-003 and CL24-004 in the Lower Current Zone and interpreted expansion of the high-grade shell.

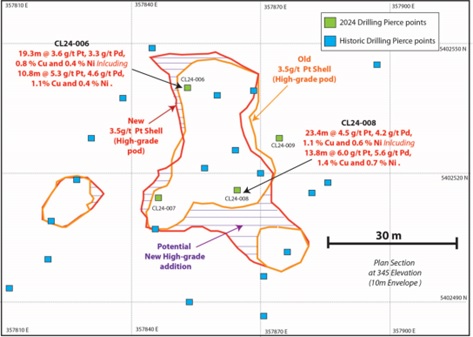

In the Bridge Zone, a flat-lying zone of high-grade mineralization was targeted as shown in plan view in Figure 3. The program was successful in expanding the volume of the target area, at grades equal to or greater than those estimated in the most recent resource model. The high-grade shell extends laterally toward the southeast, and there remains good potential for extending this shell to the west.

Figure 3. Plan view outlining drill hole pierce points in the flat-lying section of the Bridge Zone and outlining the lateral expansion of the high-grade shell. This drilling included hole CL24-008 that returned a grade of 14.20 g/t Pteq1 over 23.4m.

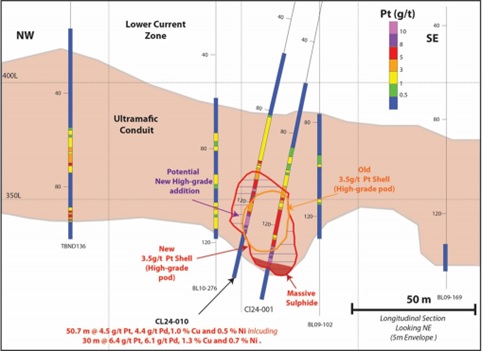

Farther northwest in the Lower Current Zone, Hole CL-24-010 added significant grade and volume to the shell along strike and Hole CL-24-002 added to the shell to the northeast (into the section) in comparison to the existing resource model (Figure 4).

Figure 4. Section outlining interpreted high grade shell expansion from hole CL24-010 (13.74 Pteq1)

Additional Massive Sulphide Intersected in Hole CL24-005

A second hole within the 10-hole program (Hole CL24-005) intersected 0.5m of massive sulphides near the base of the intrusion. The deposit is known to carry massive sulphides in pockets and embayments at both the Current and Escape deposits. These occurrences demonstrate the potential for these deposits to host additional massive sulphide, and continued exploration work is needed to identify the feeder zone for this material.

The Company is in the process of developing a follow-up exploration program designed to discover new high-grade zones within the Current and Escape deposits and a resource delineation program to support an independent resource estimate of the highest-grade domains in both deposits.

Reconfiguring the Mine Plan

The project path forward, that includes a smaller tonnage, high-grade and low-capital cost mine plan is buoyed by the results from this program. It is evident that higher-grade mineralization is spatially distributed in distinct and separable zones that allow for targeted extraction using traditional open-stoping mining methods. A bulk sample is under consideration as part of a move towards advanced exploration designation. The goal for the bulk sample will be to validate the high-grade mining approach outlined above, as well as quantify the metallurgical performance of a toll milling scenario on a larger scale.

Qualified Person

Dr. Lionnel Djon, Ph.D., P.Geo., a Qualified Person under National Instrument 43-101 and Vice President of Exploration for the Company, has reviewed and approved all technical information in this press release.

Table 1. Hole Assays

Hole ID | From | To | Length | Pt | Pd | Cu | Ni | Pt+Pd | Cu+Ni | Pteq1 |

CL24-002 | 96.0 | 127.0 | 31.0 | 2.19 | 2.03 | 0.47 | 0.27 | 4.22 | 0.74 | 6.64 |

*INCL | 105.0 | 118.0 | 13.0 | 3.71 | 3.42 | 0.74 | 0.37 | 7.13 | 1.11 |

|

CL24-004 | 101.0 | 138.7 | 37.7 | 2.09 | 1.97 | 0.46 | 0.33 | 4.06 | 0.79 | 6.56 |

*INCL | 124.3 | 132.3 | 8.0 | 4.71 | 4.41 | 1.09 | 0.71 | 9.12 | 1.80 |

|

CL24-005 | 153.0 | 191.4 | 38.4 | 3.38 | 3.26 | 0.72 | 0.45 | 6.64 | 1.17 | 10.32 |

*INCL | 178.2 | 191.4 | 13.2 | 8.39 | 8.09 | 1.75 | 0.95 | 16.48 | 2.7 |

|

*AND | 188.9 | 188.4 | 0.5 | 20.40 | 21.00 | 4.20 | 2.18 | 41.40 | 6.38 |

|

CL24-006 | 150.0 | 169.3 | 19.3 | 3.61 | 3.26 | 0.79 | 0.38 | 6.87 | 1.17 | 10.75 |

*INCL | 157.0 | 167.8 | 10.8 | 5.33 | 4.65 | 1.13 | 0.40 | 9.98 | 1.53 |

|

CL24-007 | 150.0 | 173.4 | 23.4 | 2.46 | 2.34 | 0.55 | 0.30 | 4.80 | 0.85 | 7.49 |

*INCL | 157.0 | 162.0 | 5.0 | 6.40 | 6.30 | 1.37 | 0.88 | 12.70 | 2.25 |

|

CL24-008 | 154.7 | 178.0 | 23.3 | 4.54 | 4.23 | 1.11 | 0.60 | 8.77 | 1.71 | 14.20 |

*INCL | 159.0 | 172.8 | 13.8 | 6.01 | 5.56 | 1.45 | 0.75 | 11.57 | 2.19 |

|

CL24-009 | 144.0 | 151.0 | 7.0 | 1.01 | 0.99 | 0.25 | 0.16 | 2.00 | 0.40 | 3.32 |

CL24-010 | 82.0 | 132.7 | 50.7 | 4.52 | 4.38 | 0.99 | 0.53 | 8.90 | 1.52 | 13.74 |

*INCL | 102.0 | 132.7 | 30.7 | 6.35 | 6.10 | 1.32 | 0.69 | 12.45 | 2.01 |

|

CL24-0013 | 86 | 137.8 | 51.8 | 4.92 | 4.66 | 1.07 | 0.55 | 9.58 | 1.62 | 14.82 |

CL24-0033 | 118 | 149.4 | 31.4 | 4.22 | 4.04 | 0.95 | 0.56 | 8.26 | 1.51 | 13.04 |

1. Refer to Note 1 on page 1 of this release

3. Previously reported in the September 9th, 2024 press release

Table 2. Hole Coordinates

Hole ID | Easting- | Northing | Elevation | Azimuth | Dip | Hole |

CL24-002 | 357575 | 5402659 | 490.64 | 299.23 | -78 | 162 |

CL24-004 | 357712 | 5402582 | 499.2 | 0.85 | -90 | 162 |

CL24-005 | 357967 | 5402373 | 504.5 | 337.52 | -82 | 207 |

CL24-006 | 357855 | 5402538 | 508.2 | 296.92 | -90 | 185 |

CL24-007 | 357843 | 5402512 | 508.4 | 45.31 | -89 | 185 |

CL24-008 | 357863 | 5402516 | 509.4 | 43.6 | -89 | 186 |

CL24-009 | 357874 | 5402528 | 509.7 | 346.63 | -89 | 192 |

CL24-010 | 357553 | 5402648 | 501.5 | 320.17 | -77 | 165 |

Quality Assurance / Quality Control

Clean Air Metals uses ALS Global ("ALS"), a well-established and recognized mineral assay and geochemical analytical services company. The Thunder Bay laboratory holds ISO-9000 accreditation; the Vancouver facility holds ISO-17025 registration.

All NQ-sized drill core is cut with a diamond-tipped saw blade with half of the core submitted to ALS for sample preparation and analysis. Sample preparation is completed at the ALS sample preparation facility in Thunder Bay, ON, and analysis is completed at the primary ALS assay laboratory in Vancouver, B.C.

Clean Air Metals follows a quality control procedure for its core assay sampling program: inserting blind blanks and certified Palladium-Platinum and Copper-Nickel standards into the sample stream. The insertion procedure follows industry standards with control sample frequency depending on the length of the sampled interval.

Gold, platinum, and palladium are analyzed using fire assay (FA) with an inductively coupled plasma mass spectrometry (ICP-MS) finish. Samples with grades above the optimal ICP-MS detection limits are analyzed using an optical emission spectroscopy method (ICP-OES).

Also, thirty-three (33) elements of each sample, including copper, nickel, silver, chromium, cobalt, and sulphur, are analyzed by a multi-element analytical method using the atomic emission spectroscopy (ICP-AES) technique following four-acid digestion of the sample. When samples have grades above the optimal detection limits for this analytical method, they are re-analyzed using a high-grade assay method with an ICP finish.

About Clean Air Metals

Clean Air Metals is a development and exploration company advancing its flagship, 100% owned Thunder Bay North Critical Minerals ("TBN") project, 40 km northeast of Thunder Bay, Ontario. The TBN project, accessible by road and next to established infrastructure, hosts two (2) deposits - the Current and Escape deposits, only 2.5 km apart. Together, the deposits host a 13.8 Mt indicated mineral resource containing 2.4M Pt eq. oz (Technical Report on the Thunder Bay North Project, Ontario Canada, NI43-101, SLR Consulting Canada Ltd, June 19, 2023) with significant potential for expansion down-plunge.

One of the rare primary platinum resources outside of South Africa, the TBN project is in a stable and mining-friendly jurisdiction and benefits from longstanding relationships with local First Nations. With its proven technical team, Clean Air Metals is committed to growing the resources at the TBN project and creating long-term value for shareholders.

Social Engagement

Clean Air Metals Inc. acknowledges that the Thunder Bay North Critical Minerals Project is located within the area encompassed by the Robinson-Superior Treaty of 1850 and includes the territories of the Fort William First Nation, Red Rock Indian Band, Biinjitiwabik Zaaging Anishinabek and Kiashke Zaaging Anishinaabek. Clean Air Metals also acknowledges the contributions of the Métis Nation of Ontario, Region 2 and the Red Sky Métis Independent Nation to the rich history of our area.

The Company appreciates the opportunity to work in these territories and remains committed to the recognition and respect of those who have lived, travelled, and gathered on the lands since time immemorial. Clean Air Metals is committed to stewarding Indigenous heritage and remains committed to building, fostering and encouraging a respectful relationship with First Nations, Métis and Inuit peoples based upon principles of mutual trust, respect, reciprocity and collaboration in the spirit of reconciliation.

ON BEHALF OF THE BOARD OF DIRECTORS

"Mike Garbutt"

Mike Garbutt, CEO of Clean Air Metals Inc.

Connect with us on X/ Facebook/ Instagram.

Visit www.cleanairmetals.ca for more information or contact:

Mia Boiridy

Director of Communications and Investor Relations

250-575-3305

[email protected]

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Note

The information contained herein contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements." Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: political and regulatory risks associated with mining and exploration; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company's expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Investors are cautioned against attributing undue certainty to forward-looking statements. These forward-looking statements are made as of the date hereof, and the Company does not assume any obligation to update or rvise them to reflect new events or circumstances except in accordance with applicable securities laws. Actual events or results could differ materially from the Company's expectations or projections.

SOURCE: Clean Air Metals, Inc.